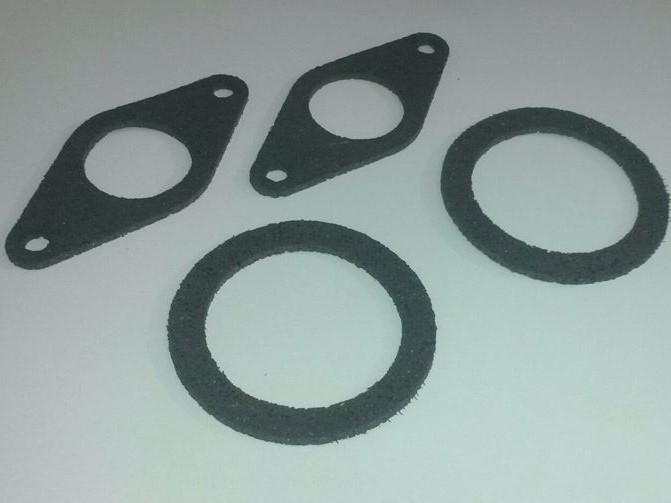

This material represents the passed history of a solution adopted so as to realise electrical continuity between surfaces by way of metallic fillers interposed according to a certain defined diameter and density. Monel or Aluminium wires and solid or expanded silicone may be ordered.

Where watertight sealing and EMI shielding are required. In that the product is still utilised, it is irrefutable that today, because of its negative aspects, it is substituted in nearly every case with silicones loaded with conductive fillers. To list some of the negative aspects, infiltration of humidity or water along the metal wires covered by the silicone material, which come into contact with the surface and at points, may cause corrosion on aluminium or other metals. Then there is the risk of the breakage upon compression of the metal wires during crushing.

Where watertight sealing and EMI shielding are required. In that the product is still utilised, it is irrefutable that today, because of its negative aspects, it is substituted in nearly every case with silicones loaded with conductive fillers. To list some of the negative aspects, infiltration of humidity or water along the metal wires covered by the silicone material, which come into contact with the surface and at points, may cause corrosion on aluminium or other metals. Then there is the risk of the breakage upon compression of the metal wires during crushing.